Rising environmental awareness and energy shortages caused by the nuclear accident in Fukushima has led to an increase in biomass power generation plants that burn factory waste and other normally discarded materials to produce power. In response, we have created a product lineup of chains for biomass power generation facilities. The chains have superior wear and corrosion resistance.

An extensive lineup of long-lasting chains designed for specific conveyance needs

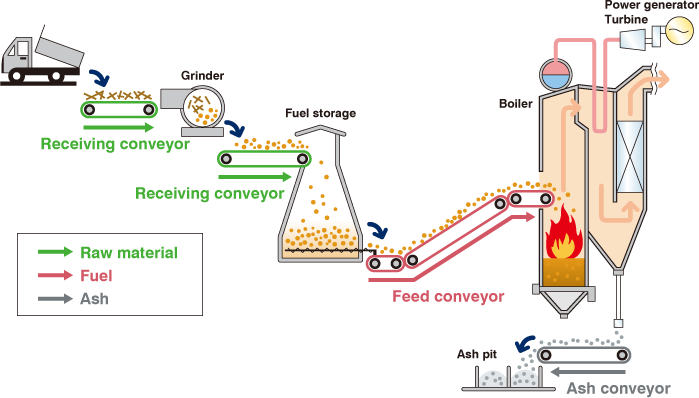

Biomass is organic matter that can be re-used to benefit the environment. It includes materials such as wood chips, lumber, discarded tires, and lime, all of which can be burned in boilers to generate electricity. Conveyors are used to receive these materials, feed them to the boilers, and convey the resulting ash. We have developed our chains for biomass power generation facilities to be the optimal solution for the performance demanded for such conveyance processes, and we have already started to deliver them to a variety of customers, including independent power plant operators, as well as paper manufacturers and cement manufacturers that operate their own power generation plants.

How biomass power generation works

This product series consists of four different types of chain categorized into two different conveyance methods and two different states of the biomass and ash being conveyed, either dry or wet. Choosing the right chain for the job will extend its service life.

Chain for conveying dry matter emphasizes wear resistance, and we have improved its hardness by applying a special heat treatment to the material. Chain for conveying wet matter employs material that stands up to corrosion and rust, thereby raising its wear resistance along with its corrosion resistance. Furthermore, both types employ ingenious designs to prevent the matter being conveyed from accumulating in chain gaps.

In developing these products, we worked with our customers to collect actual data on chain wear and other performance items. While there were difficulties associated with conducting studies at live power plants, it enabled us to develop within about one-year period a chain product that has about double the life of our previous product.

Flight Conveyor Chains

Trough Conveyor Chains